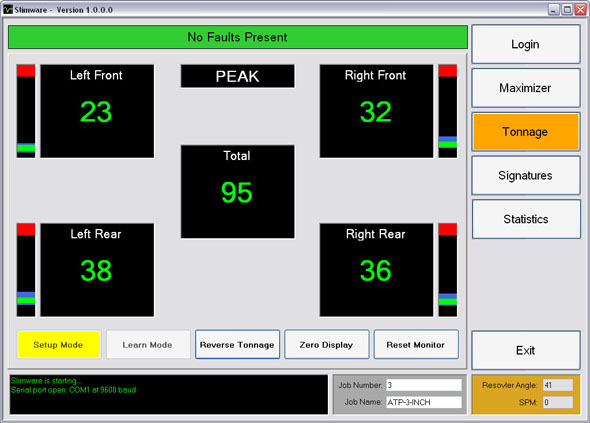

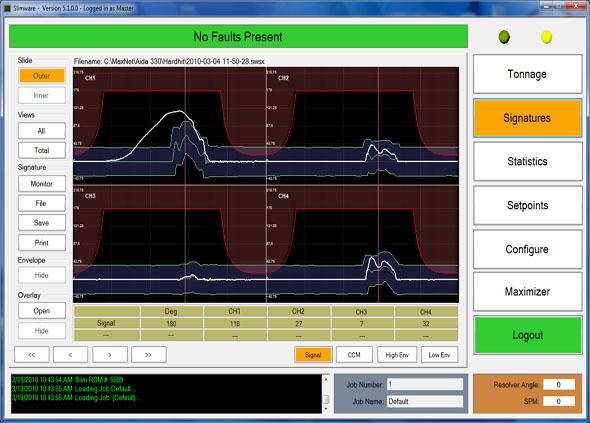

Every press manufacturer provides a press-rated tonnage curve and motion diagram, which can be uploaded into our SLIM monitor. This curve is then plotted against the actual tonnage signature and can be viewed through the user interface software, SlimWare.

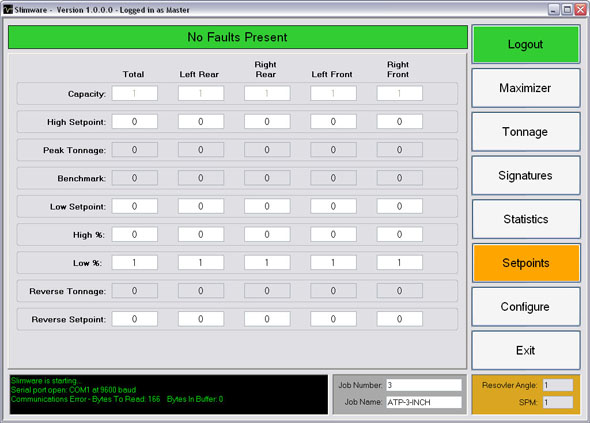

The SLIM's onboard memory allows for operators/setup personnel to retrieve the last 25 signatures. Along with signatures, setpoints can be saved and loaded with each job. These setpoints include:

- Capacity

- CCM (Critical Curve Monitoring)

- High Setpoint

- Low Setpoint

- High Enveloping (5-Zones)

- Low Enveloping (5-Zones)

- Reverse Setpoint

The SLIM can also interface with a wide variety of equipment ranging from the most sophisticated Allen-Bradley & Siemens programmable logic controllers (PLCs) through the use of OPC server/client tags, to standard personal computers (PCs) through the use of standard text files.

The SLIM unit also provides a standard option of data-logging. This option saves any alarm, setpoint or configuration change to a text file along with a timestamp and user ID. This can provide a detailed history of any alarms or changes made to the SLIM unit.

For a more detailed alarm history, our PressNet and MaxNet networking packages allow for detailed reporting by time, press, user and types of alarms.

The SLIM unit comes standard with the user interface software, SlimWare. This software can be installed on any desktop/industrial PC with the following operating systems:

- Microsoft Windows 2000

- Microsoft Windows XP

- Microsoft Windows XP Embedded

- Microsoft Windows Vista

- Microsoft Windows 7

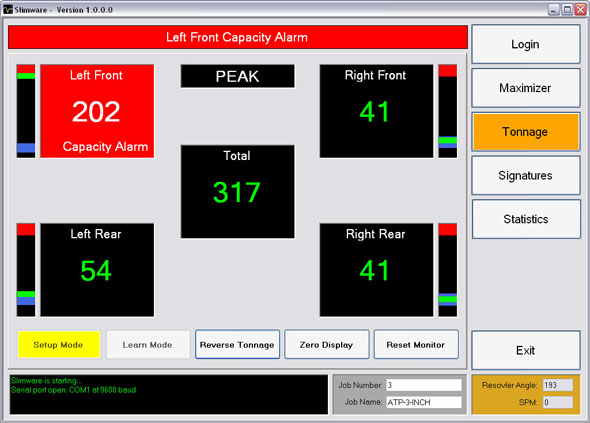

Sample SlimWare

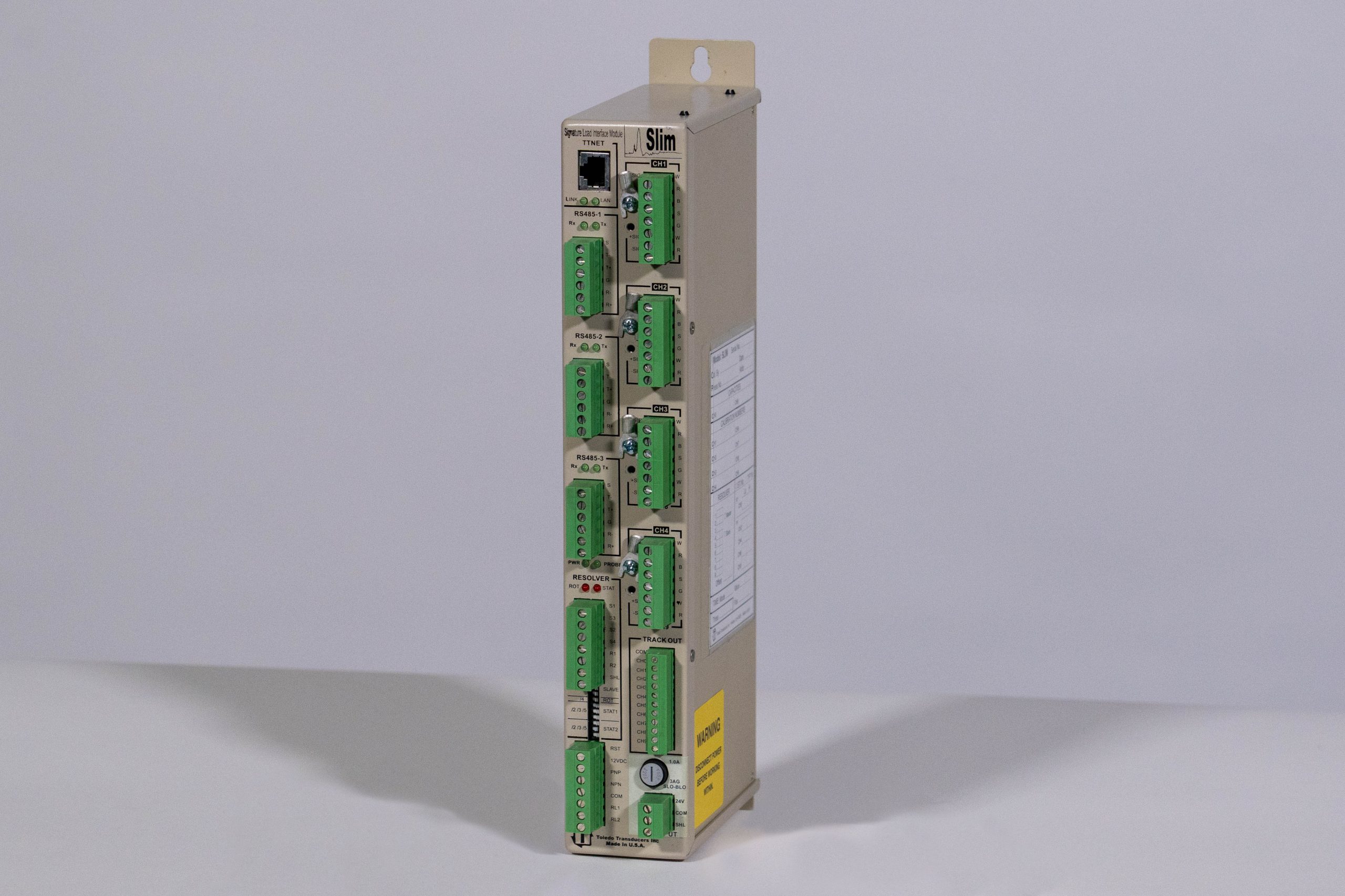

| Standard | Option | |

| Signal conditioning module for strain gauge sensors & load cells |

✓ | |

| Four independent channels for accommodating up to eight sensors |

✓ | |

| Uses full-bridge sensors from 120 Ohms to 1,000 Ohms |

✓ | |

| Plug-in connectors are used for the sensor inputs |

✓ | |

| High/low sensitivity span ranges selected with front panel switch |

✓ | |

| Power input/output are plug-in connectors |

✓ | |

| Built-in automatic peak load memory circuits |

✓ | |

| Peak measurements are made with an external trigger device |

✓ | |

| Built-in power supply for stable operation and noise rejection |

✓ | |

| Compact size to fit almost any location | ✓ | |

| Steel enclosure for maximum protection and noise rejection |

✓ | |

| Automatic Zero Balance | ✓ | |

| From one to eight sensor inputs, one or two per channel |

✓ | |

| Analog output terminals | ✓ | |

| CE Certified | ✓ | |

| PLC Ladder Logic | ✓ | |

| HMI Screen Program | ✓ |

| No. Of Channels | Two,Four,Six or Eight |

| Sensor Inputs | Full bridge strain gauge sensors 120 to 1000 ohms Up to (16) 350 ohm sensors |

| Sensor Excitation | Built-in 10VDC @ 500mA max (Short circuit protected) |

| Sensor Input Connections |

7-pin .2" pitch Phoenix connector |

| Auto-Zero Time Constant |

N/A |

| Balance Range | +/- 1mV/V of offset |

| Gain Range | 100-11,000x (digitally controlled) |

| Analog Output | 1.25VDC @ Press Capacity |

| Analog Output Connection |

11-pin .15" pitch Phoenix connector |

| Peak Delay | N/A |

| Accuracy | +/- 1% of full scale max |

| Non-linearity | +/- .1% of full scale max |

| Frequency Response |

Flat DC to 6KHz |

| Resolution | Each channel provides a 4-digit load value in 1024 count resolution |

| SPM | 800 SPM (resolver trigger) |

| Calibration Shunts | Calculation based on 1 Meg Ohm shunt resistor |

| Computer Interface |

(3) RS-232/422 serial ports (38.4K - 460K baud) |

| Trigger | Resolver, Probe or Threshold |

| Threshold Probe | Built-in voltage source (12VDC @ 80mA max) provides power for NPN or PNP proximity probes. Also supports limit switch, solid state or mechanical relays |

| Resolver Interface | Built-in excitation supports standard 5000Hz rotor excited positional resolver |

| Shutdown Relay | 8A @ 250VAC or 30VDC N.O. Contact (N.C. Optional) Bypass switch available |

| Power Req. | 29 Watts max, 85-132VAC @ 50-60Hz OR 170-264VAC @ 50-60Hz (Use .25" x 1.25" SLO-BLO fuse) |

| Expansion | Interface port for I/O module |

| Operating Temp. | 0-70 degrees Celsius |

| Weight | Approximately 7.0lbs |

| Width | Height | Depth | |

| Dimensions | 2.125 " | 12.0 " | 5.0 " |

| Name | Format | Link |

| SLIM User Manual | ||

| SlimWare V4 User Manual (SLIM-RV1) | ||

| SlimWare V7.1 User Manual (SLIM-RV2) | ||

| SlimWare V5 Demo | EXE |  |