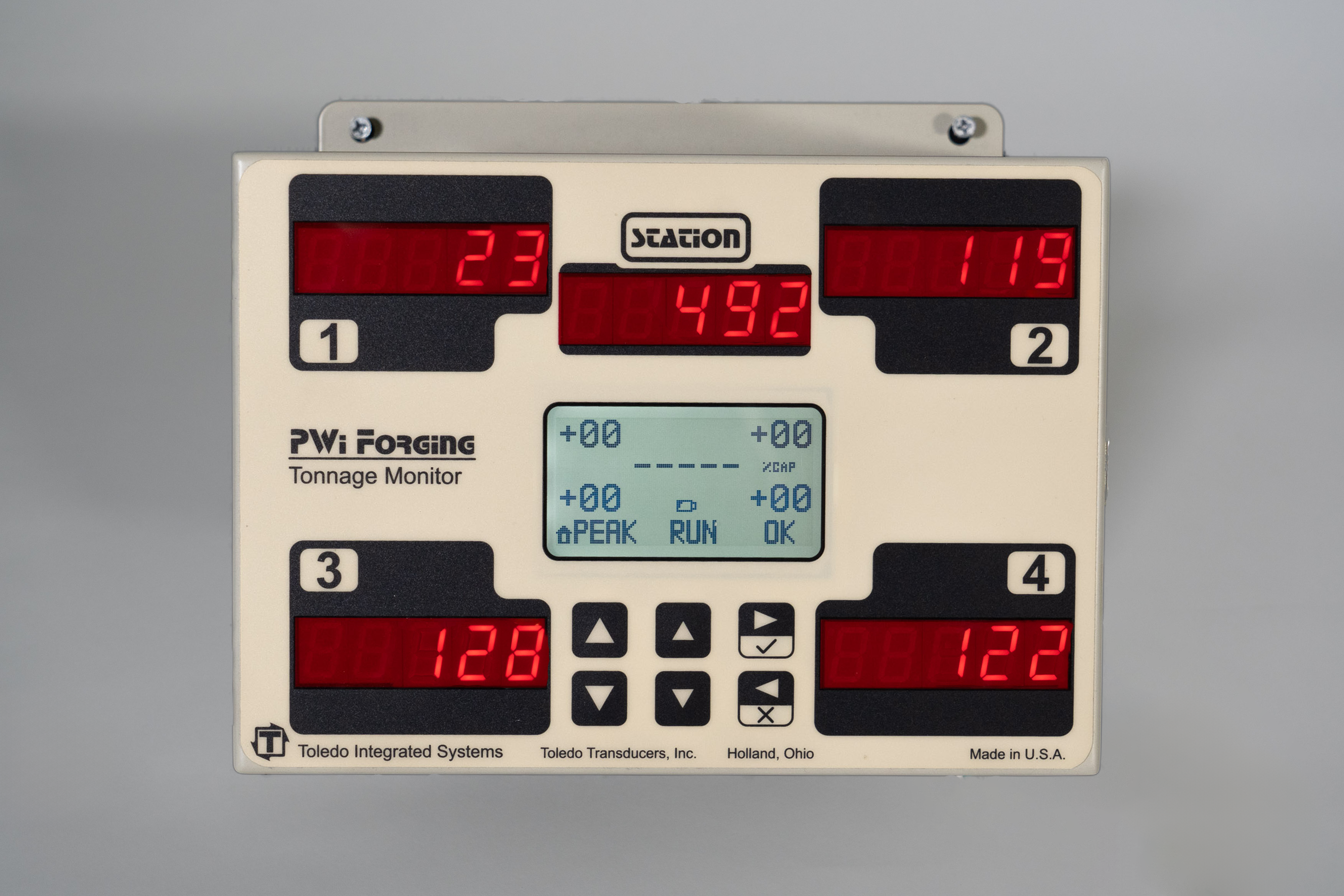

The PWi Forging instrument monitors multiple press tonnages during the forming of a single part.

The forming tonnage for up to four unique die stations can be displayed and each station has it's own set of tonnage limits. Each set of tonnage limits is based on a benchmark value unique to the station using the convenience of AUTO-SET. The PWi Forging monitor displays the forming tonnage for each station sequentially.

Station #1 shows the tonnage developed in the Buster operation. Station #2 shows the tonnage that is generated in the Blocker operation and so on up to four stations. Once the sequence is completed, the forging monitor assumes that a new part is starting and returns to Station #1 again. Time based (standard) and resolver based (optional) tonnage signatures are viewed on the LCD screen, along with tonnage limit settings, alarm history, job storage, deviation and more.

| Standard | Option | |

| Monitor up to four stations | ✓ | |

| Reverse Load Display | ✓ | |

| Signature Analysis - Time Based | ✓ | |

| Resolver Input For CCM | ✓ | |

| Menu-Driven User Interface | ✓ | |

| (2) Shutdown Relays (Top & Immediate) | ✓ | |

| 100 Job Storage | ✓ | |

| (1) RS422 / (PressNet) | ✓ | |

| Ethernet Port | ✓ | |

| PressNet V5 Compatible | ✓ | |

| 120VAC Input Power | ✓ | |

| 24 VDC Input Power (DC version is compliant with European CE standards) |

✓ |

| No. Of Channels | Two, Four or Eight |

| Sensor Inputs | Full bridge strain gauge sensors |

| Analog Output | .25" stereo phono jack 2.5VDC @ Press Capacity |

| Display | Back-lit 1.5"x2.75" LCD graphical display (64 x 128 pixel) (5) Led displays, each consisting of five 7-segment displays |

| Keypad | Menu-driven keypad consisting of six tactile switches |

| Job Storage | 100 |

| Resolution | Each channel provides a 5-digit load value |

| Serial Port 1 | RS422(9,600 to 115,200 baud) for PressNet software interface |

| Serial Port 2 & 3 | RS422 (9,600 to 115,200 baud) for data transfer |

| Probe Input | Built-in voltage source provides power for the probe. It supports

NPN/PNP proximity probes, and solid state or dry contact relay. |

| Shutdown Relays | Top Stop relay and Immediate Stop relay

(Mechanical relay with N.O. and N.C. contacts) |

| No. Of Channels | Two, Four or Eight |

| Sensor Inputs | Full bridge strain gauge sensors |

| Analog Output | .25" stereo phono jack 2.5VDC @ Press Capacity |

| Display | Back-lit 1.5"x2.75" LCD graphical display (64 x 128 pixel) (5) Led displays, each consisting of five 7-segment displays |

| Keypad | Menu-driven keypad consisting of six tactile switches |

| Job Storage | 100 |

| Resolution | Each channel provides a 5-digit load value |

| Serial Port 1 | RS422(9,600 to 115,200 baud) for PressNet software interface |

| Serial Port 2 & 3 | RS422 (9,600 to 115,200 baud) for data transfer |

| Probe Input | Built-in voltage source provides power for the probe. It supports

NPN/PNP proximity probes, and solid state or dry contact relay. |

| Shutdown Relays | Top Stop relay and Immediate Stop relay

(Mechanical relay with N.O. and N.C. contacts) |