Toledo Integrated Systems has been providing solutions to the metal forming industry for over 30 years.

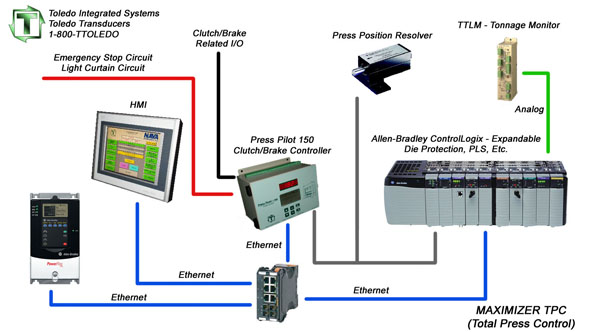

In that time we have worked with various hardware platforms including PLC5, SLC, MicroLogix, CompactLogix and ControlLogix. Our Maximizer TPC has many standard control and automation features but allows for easy customization and expandability.

The Max TPC is built to order with all the functionality and integration that the customer requires. This gives the customer complete control of the equipment using standard "off-the-shelf" hardware. The HMI is also selectable. Along with the standard offerings for the HMI, we are capable of providing an industrial PC or a screen from a different vendor (if you have standardized on a certain screen).

Below is a list of the standard features and options for the Max TPC. The options don't stop there. The true advantage with a PLC system is that it can be expanded and customized to the customer's exact needs.

All supplied controls comply with OSHA, ANSI and CSA Z142-02 regulations for mechanical stamping presses.

- Protected memory (each processor)

- Anti-tie down protection

- Anti-repeat protection

- Single and double action modes

- Input status diagnostics

- Monitored force guided relays for safety related outputs

- Dual channel monitored E-stop safety circuit

- Inputs for two operators

- Fault & prompt messaging

- Light curtain & guard interlocks

- Pressure monitoring

- Oil temperature display

- Lube system control & monitoring

- Hydraulic pumps control & monitoring

- Leveling and IMC interface I/O & Logic

- Press position (linear transducer)

- Press SPM display

- 50 job storage

- 8 die protection stations

- 8 programmable limit switches

- 2 or 4 channel tonnage monitoring

- Counters (part, stroke and batch)

- Return from position (tonnage)

- Online help menus

- Multi-level password protection

- Enclosure air conditioner